Making the Lilla End Table

One last retrospective before getting back to real-time blogging! This is the second piece I’ve made since moving into the new studio. I still had no workbench at this point and relied on my father’s old Black & Decker Workmate.

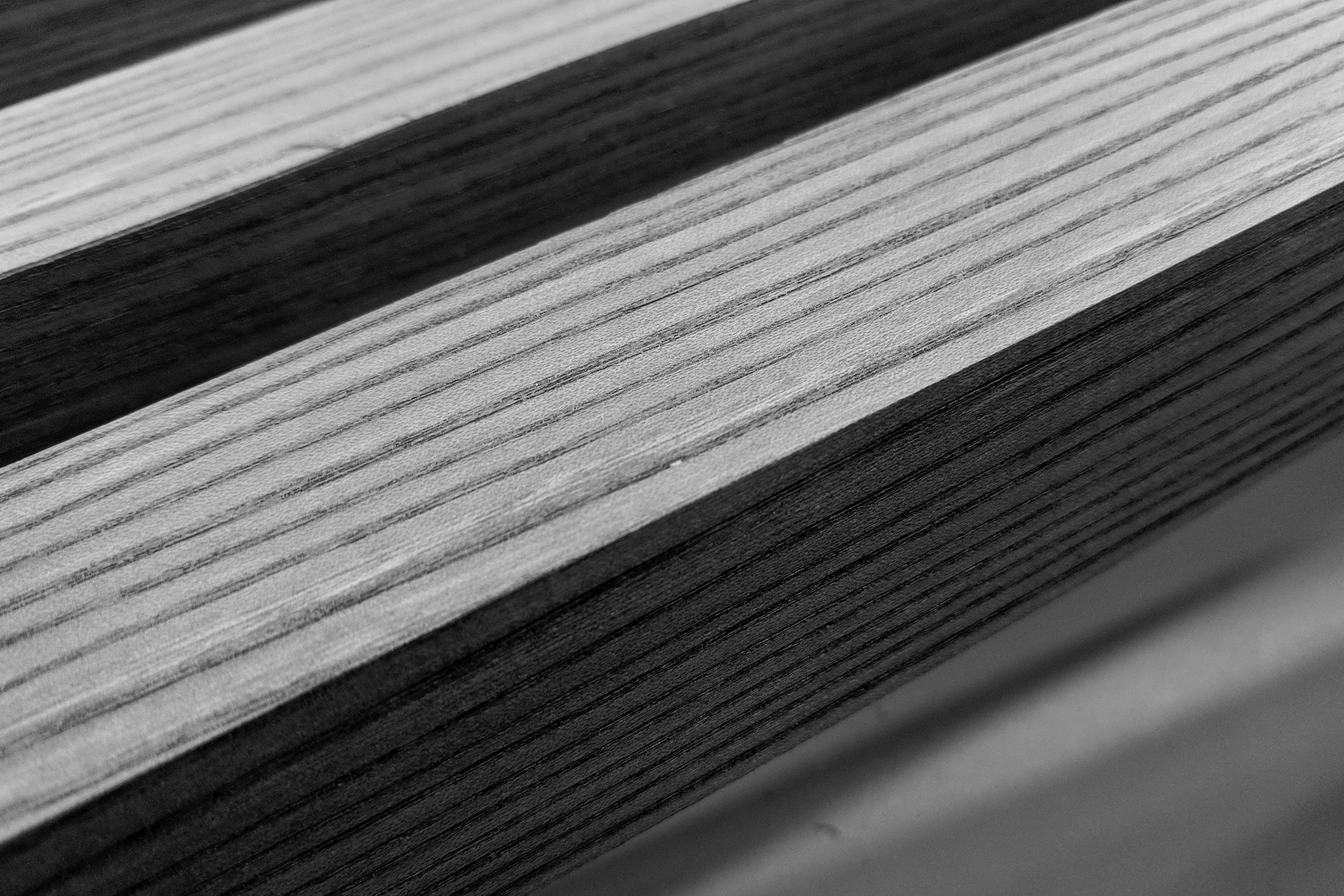

This piece was made in preparation for the American Craft Council Saint Paul Show in April of this year; a small end table made of red elm harvested in the Twin Cities of Minnesota. The piece was designed around a small plank of wood I’ve had in my shop for several years.

Just 13 parts.

The grain lines appear very “ash-like”, but the reddish color quickly gives it away as red elm. (you’ll have to check out the finished piece photos in the gallery to see some color!)

Below, a quick dry-fit of the mortise and tenon joinery prior to final shaping.

Ah, that’s better. Lighter, with subtle curves.

Elm can be a bit nasty when it comes to changing grain direction and getting fiber tear-out, but this red elm was fairly tame in that regard.

A bit of edge softening and we’ll be ready for glue-up.

Glue-up.

Final surface prep on the top.

This piece was finished with two coats of the usual Krenovian 1:1:1 blend of Waterlox Original, pure tung oil and mineral spirits.

Now to mount the top.

I cut some short lengths of brass bar stock…

… and followed that with some rabbets cut with an end mill on the mortiser.

The rabbets fit together to hold the top down onto the upper stretchers, while at the same time allow for seasonal movement of the top.

Following a trip to the ACC show, this piece made it down to Northern Woods, an exhibition sponsored by the Minnesota Woodworkers Guild.

Well, you’re all caught up for now. Next time, I’ll show you progress I’ve been making on the liquor cabinet made of yellow cedar and Honduran mahogany.

Hej då!

Craig